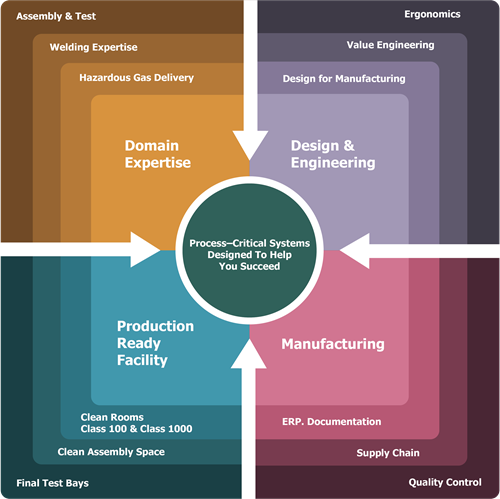

Single Source Semiconductor Equipment Solutions

We work with semiconductor customers from prototype to production. In addition to our extensive domain expertise and manufacturing excellence, including diligent ERP documentation and supply chain management, Dakota’s production-ready facility features class 100 & 1000 clean rooms, clean assembly space, and final test bays to run complete semiconductor equipment testing and validation before we ship. Learn more about a Dakota partnership and the Dakota Difference.

Semiconductor Equipment Design

Dakota Systems has the knowledge and fabrication expertise to meet your semiconductor equipment design needs. Our staff of engineering and applications personnel can complete your initial designs while providing valuable recommendation of industry best known methods and system safety components.

- CAD Design: AutoDesk Inventor, Autocad, SolidWorks and Pro-E

- Project and Product Manager experience

- Equipment Code and SEMI Standards Knowledge

- Certified UL 508A Wiring, Harness Assembly and Controls Capability

- Standard Dakota gas source delivery solutions

Semiconductor Capabilities & Resources

Dakota's strength is in its people. Our team of manufacturing and engineering professionals have the talent and experience to design, manufacture and test the most complex semiconductor process systems. We provide solutions from simple weldments to completed process equipment.

We believe that all subsystems and completed process tools should be fully functional tested prior to shipping from Dakota. To achieve this standard, Dakota has 3 cleanrooms and 4 industrial test stations. Critical Systems are fabricated, assembled, and tested in our Class 100, Class 1000, Class 10,000 clean room facilities, including:

- Semi grade gas- Argon, N2, He, CDA

- 1 Meg cooling water

- 18 M-ohm DI water system

- 3 phase high voltage electrical supply (480V, 300A capability)

- Vacuum and Cryopump Exhaust

- Helium Leak Testing Standard

- High Pressure Testing available

- High Bay and Overhead Crane

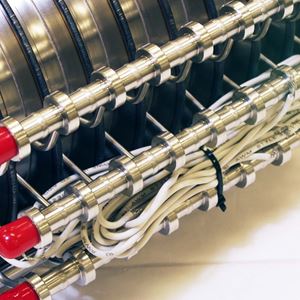

Semiconductor Equipment Manufacturing

Over 30 years' experience in gas delivery systems and process equipment goes into Dakota's semiconductor equipment solutions. We design and manufacture upon three pillars: Safety, Scalability, and Synthesis between the laboratory ecosystem and the process equipment.

Semiconductor Equipment Products

We offer a full range of proprietary semiconductor equipment and gas delivery equipment. Contact Us to learn more.