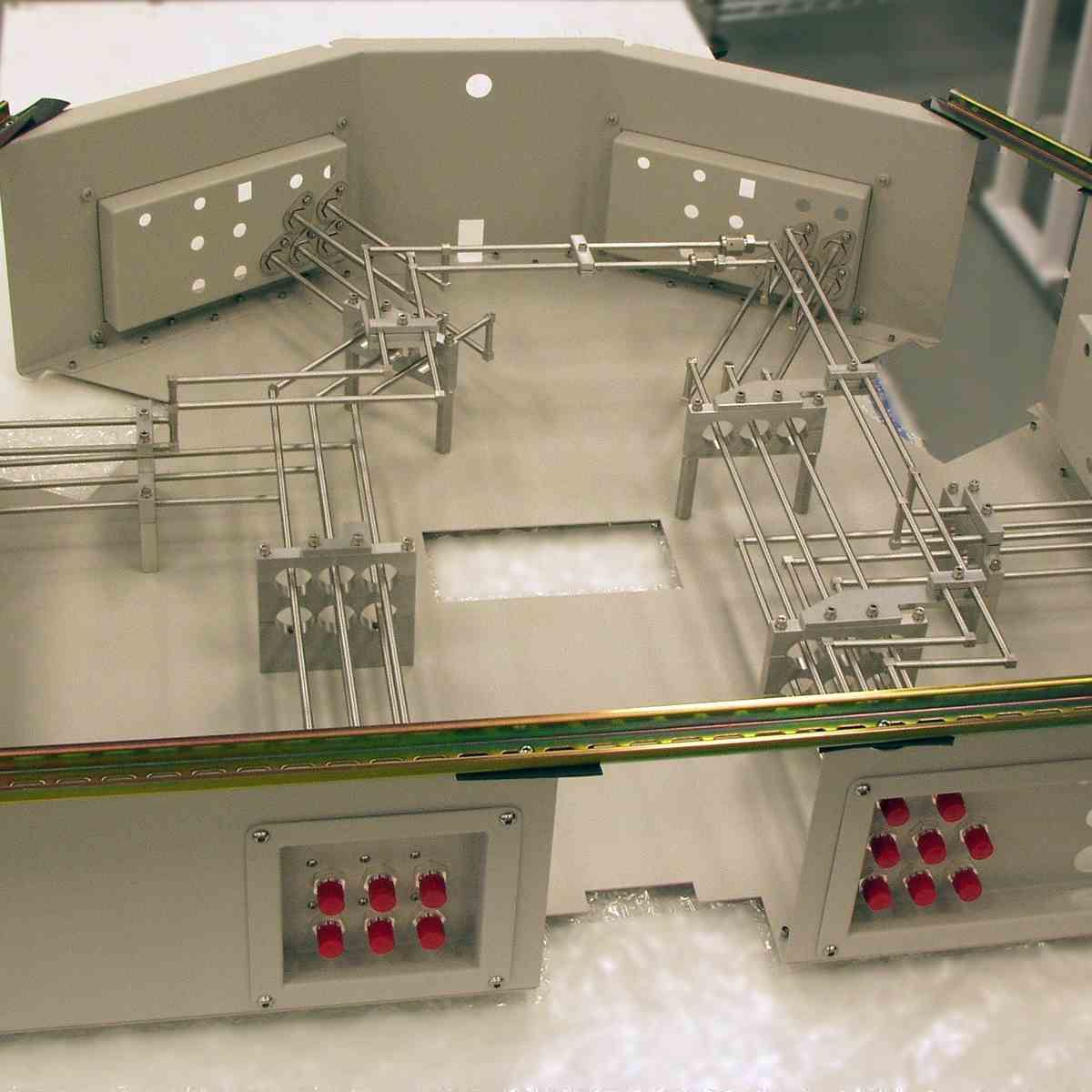

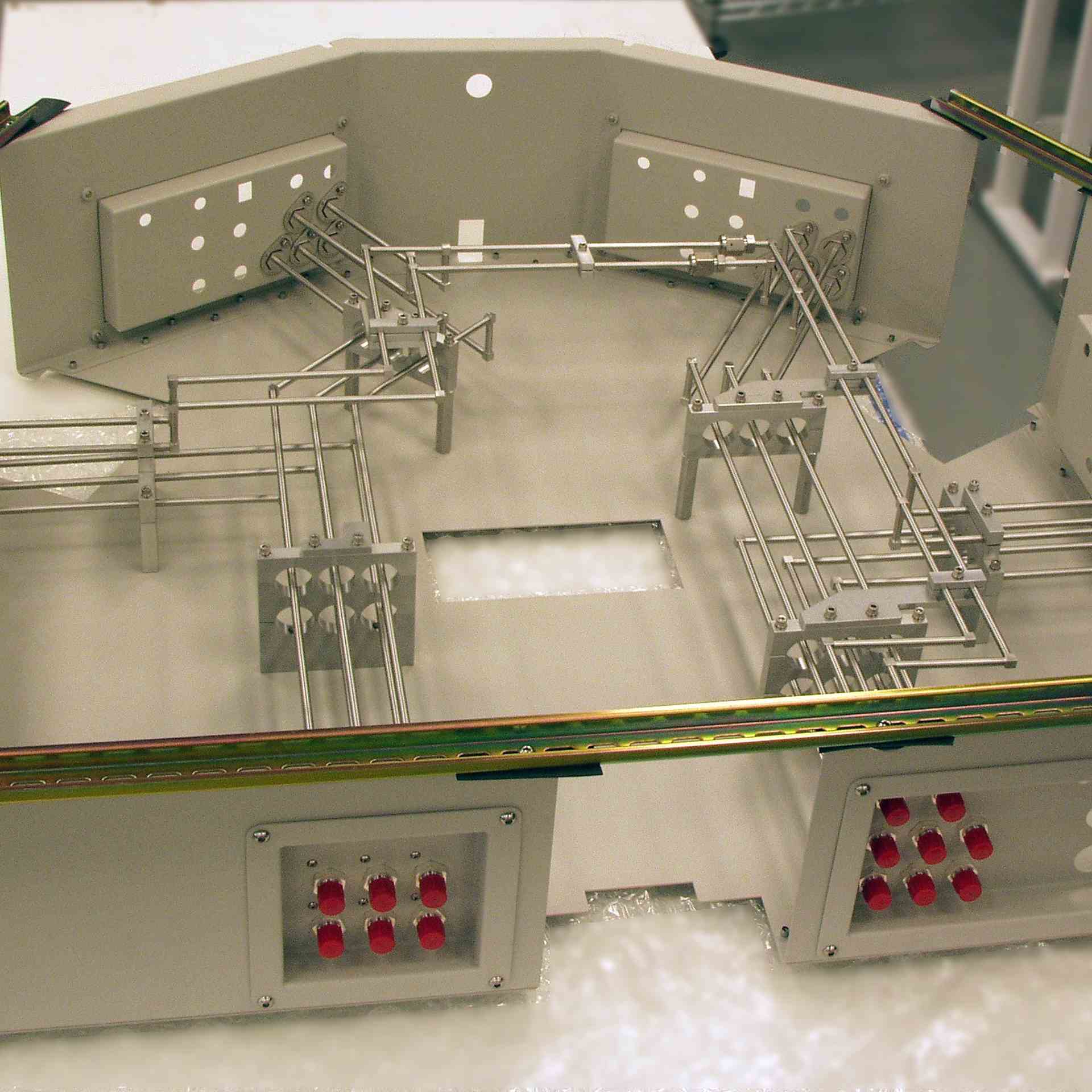

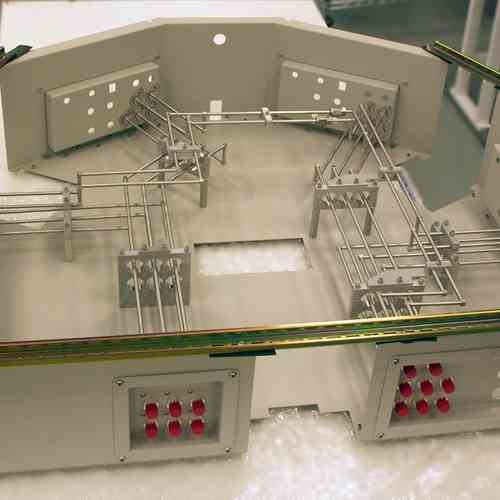

Design & Manufacturing

Laboratory Design Solutions

We apply more than 30 years’ experience in gas delivery systems and process equipment to our laboratory design solutions.

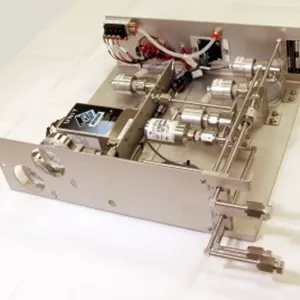

Scalable Gas Delivery Services

Scale is the nucleus of Dakota’s laboratory equipment design and manufacturing philosophy. Our laboratory design solutions leverage standardization, flexible design, and best practices to create scalable gas delivery systems that improve current and future lab performance.

More than 30 years of design expertise and manufacturing inform the Dakota Standard. All of our laboratory equipment and systems feature design elements to facilitate installation and maintenance, enable growth and adaptation, and improve daily ownership. Features include:

- Gas delivery systems with unions at standard distances to support current and future equipment throughout the facility.

- Uniform gas inlet and exhaust ports to improve flexibility and keep gas lines clear from damage and accidents.

- Compatible design specification to enable next-generation laboratory equipment to leverage the existing laboratory and equipment.

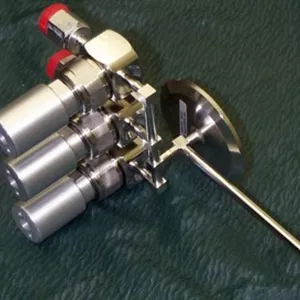

Ergonomic Laboratory Gas Piping

Our comprehensive knowledge of the laboratory equipment domain from the gas source to the process laboratory equipment enables us to design and manufacture ergonomic laboratory gas piping systems and equipment. We not only consider the ease of the initial set-up, but make maintenance items accessible and operation simple. The net result is improved efficiency and productivity through equipment that is a joy to own.