Featured Systems

Why Dakota

Domain Expertise

The combination of our domain expertise, design and engineering, manufacturing capabilities, and production-ready facility empower our partners with exceptional process equipment, low cost of ownership, and scalable manufacturing that adapts to demand.

- Industry Knowledge

- Welding Expertise

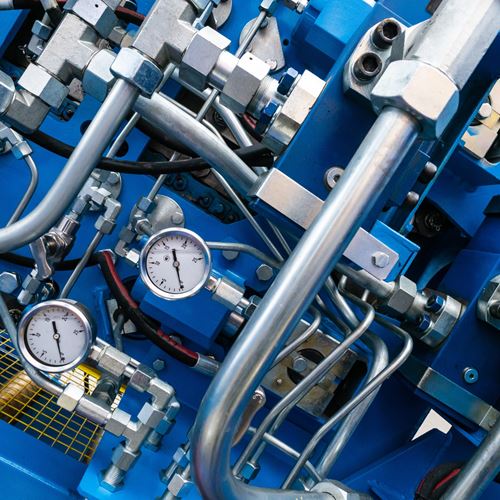

- Hazardous Gas and Liquid Delivery

- Product Lifecycle Partnership

- Design and Engineering

Our Services

Full range of gas & fluid system capabilities

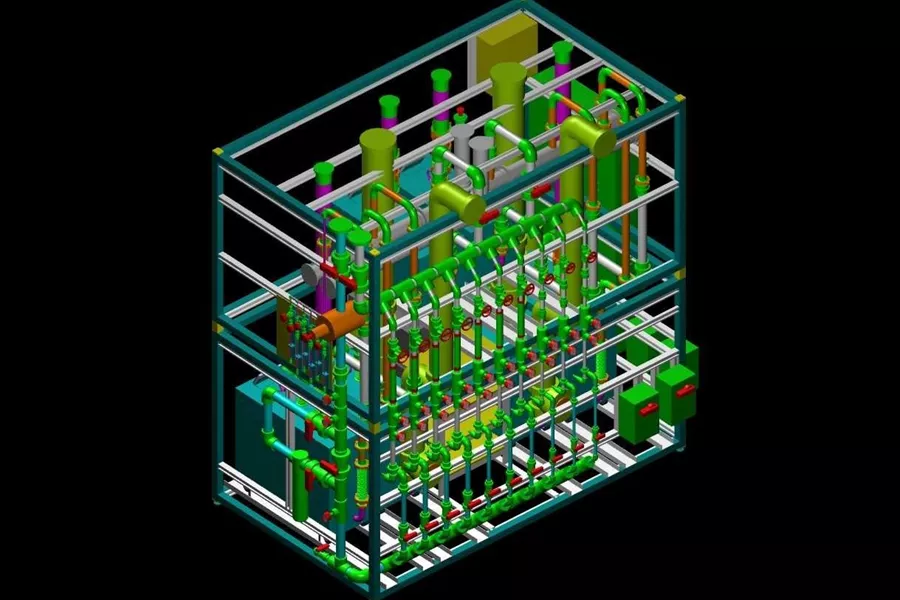

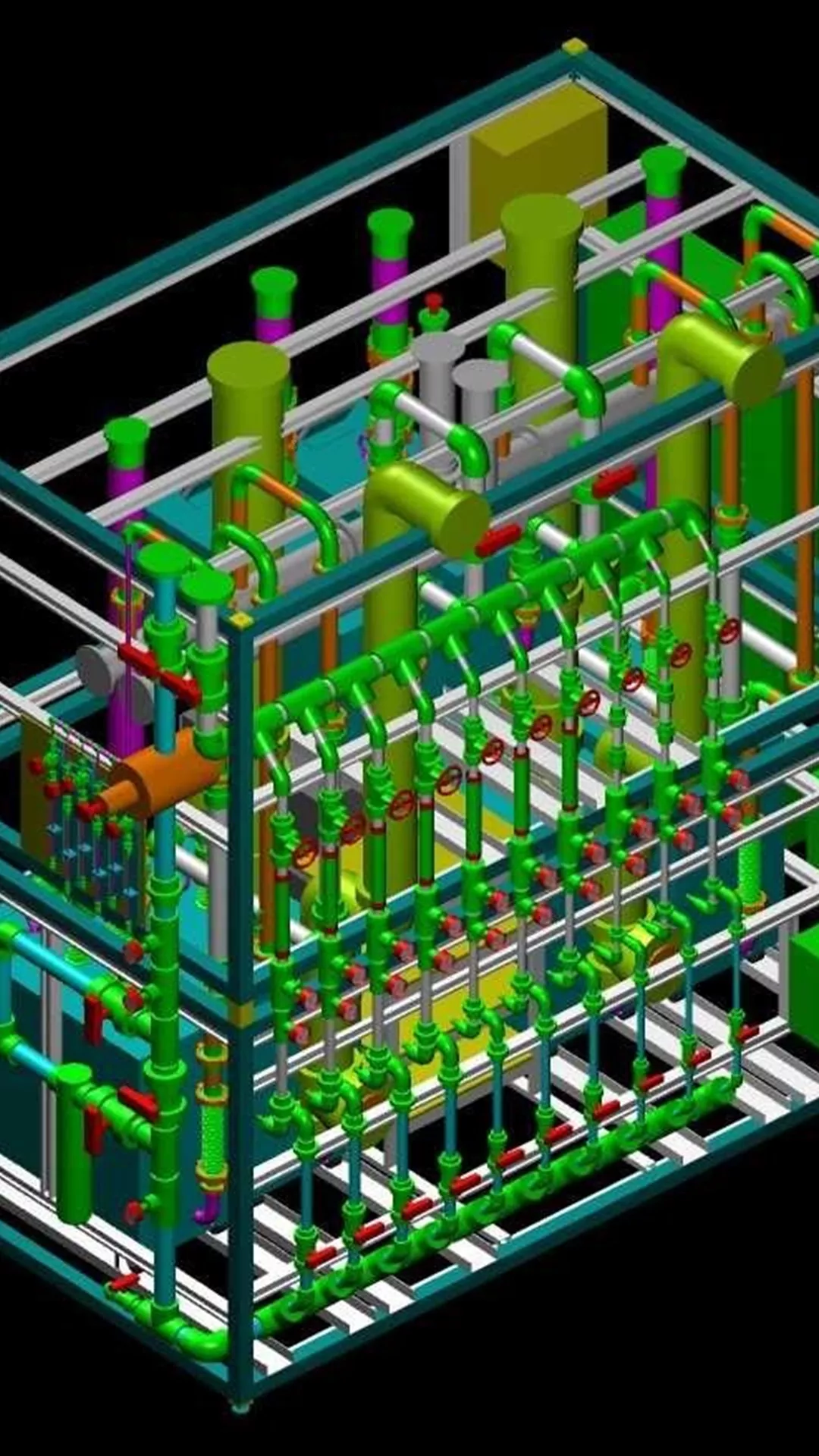

Design & Engineering

Optimize Your Design

We pride ourselves on our consideration of cost of ownership and value-added engineering. We make equipment that is durable, easy to maintain, and designed around both the process and the end user.

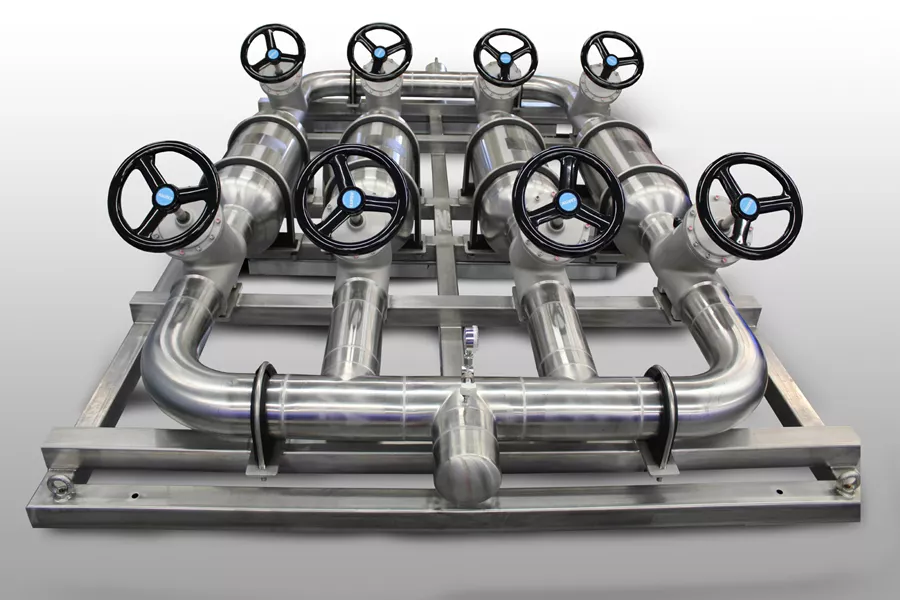

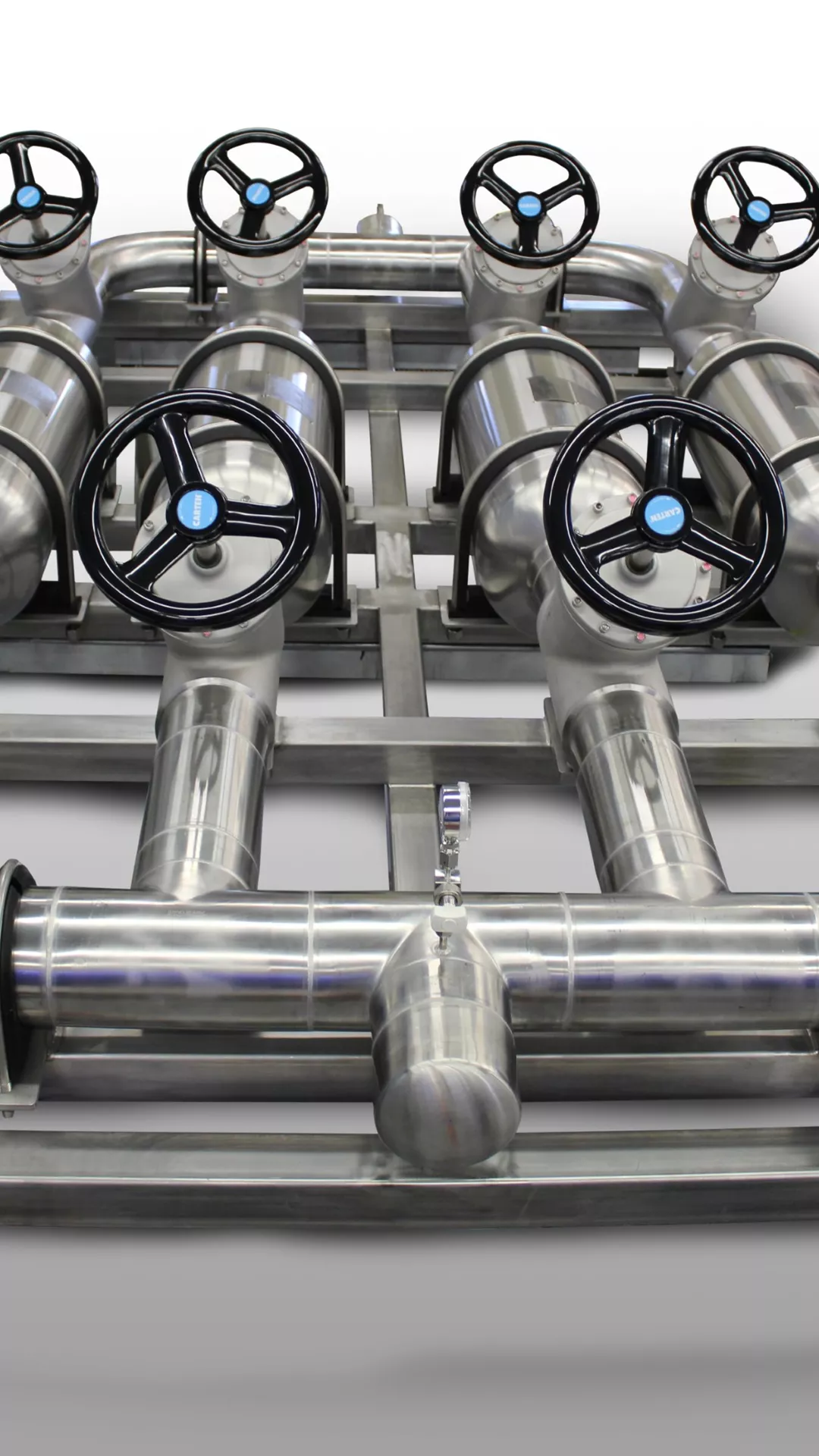

Manufacturing

Manufacture Your Product

Dakota Systems documents the manufacturing process to ensure quality and scalability. Our customers have no overhead manufacturing costs yet are able to ramp production to meet demand.

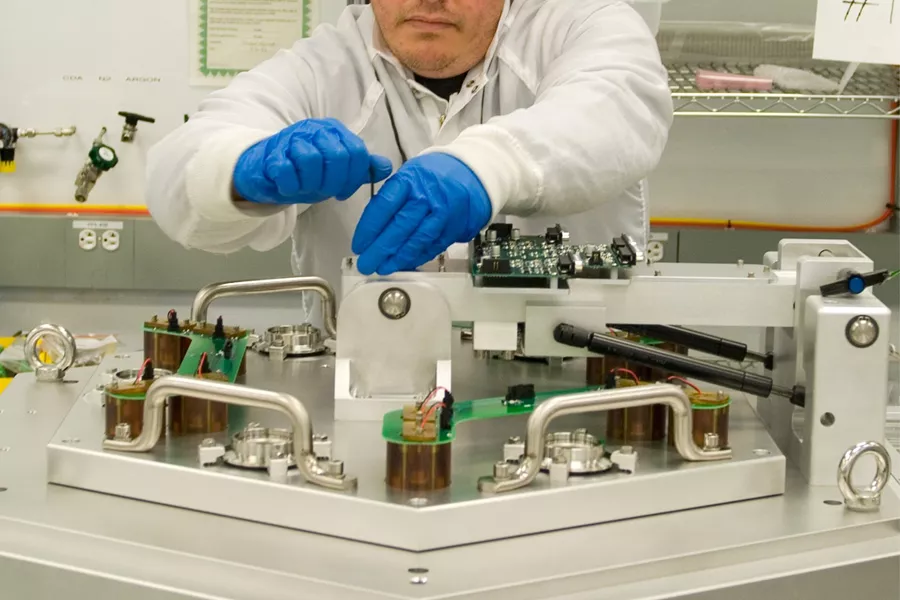

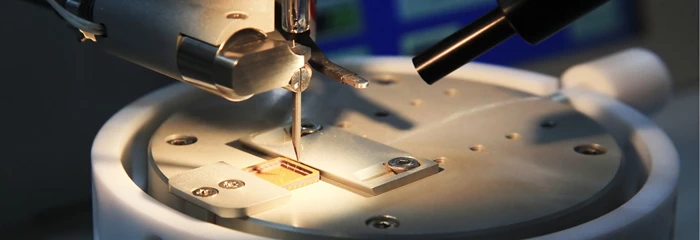

Validation & Testing

Production Ready Facility

Dakota's facility includes Class 100 & 1000 clean rooms, clean assembly space, and final test bays. Our ability to run full-function testing gives us a deeper understanding of how the process equipment was designed and how it functions.

Case Studies

Process-Critical Systems Designed To Help You Succeed

Featured Article

Proud 2016 Massachusetts Manufacturing Caucus Award Winner

On October 26, 2016 John M. Thomas, President of Dakota Systems, proudly attended the first annual Manufacturing Caucus Award Ceremony at the State House in Boston, MA along with State Officials and Legislators.

35+ Years

Kevin Lear of NNE Pharmaplan shares his experience working with Dakota Systems at the 30 Year Anniversary Celebration.